| PARTICULARS FOR MECHANICAL PROPATIES TEST |

| |

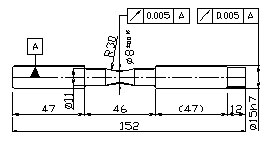

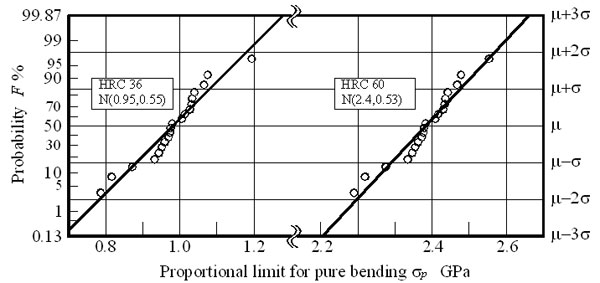

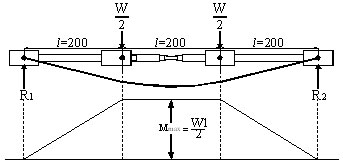

| Pure bending test properties |

| |

| Table.1 Test piece properties |

| Hardness |

HRC36,60 |

| Geometry |

|

|

|

| |

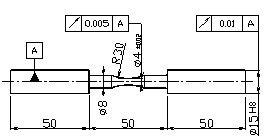

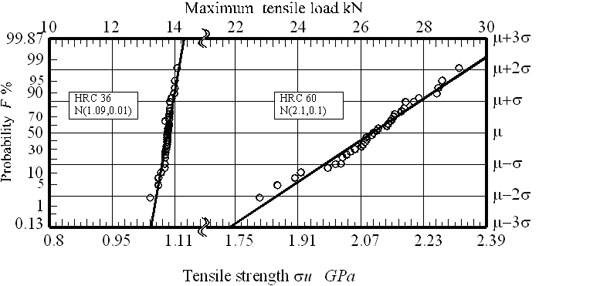

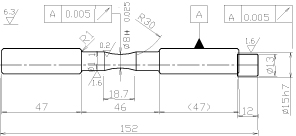

| Tension test properties |

| Table.2 Test piece properties |

| Hardness |

HRC36,60 |

| Geometry |

For HRC36

For HRC60 |

|

|

| |

| Table.3 Mechanical properties for piece |

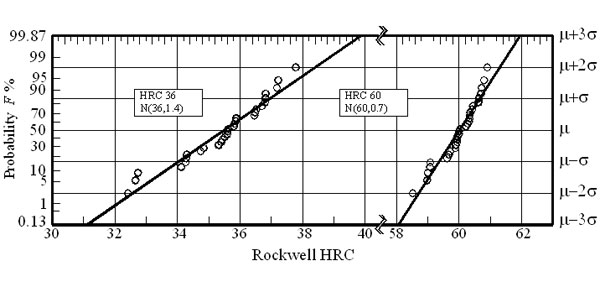

Rockwell hardness [HRC] |

N (35.6, 1.452) |

N (60, 0.652) |

Proportional limit for bending [GPa] |

N (0.947, 0.552) |

N (2.38, 0.532) |

Tensile strength [GPa]

|

N (1.09, 0.0142) |

N (2.1, 0.122) |

|

| |

| |

| Table.4 Heat treatment conditions of SUJ2 steel |

Hardness |

Normalizing |

Quenching |

Tempering |

HRC36 |

- |

830℃/20min |

170℃/120min |

HRC60 |

- |

830℃/20min |

600℃/90min |

|

|

| |

| Table.5 Chemical composition (mass%, O: ppm) |

| |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Cu |

O |

| Product analysis |

0.98 |

0.18 |

0.37 |

0.016 |

0.003 |

1.42 |

0.03 |

0.07 |

0.12 |

6 |

| Requierment |

Max |

1.10 |

0.35 |

0.50 |

0.03 |

0.03 |

1.60 |

0.08 |

- |

- |

- |

| Min |

0.95 |

0.15 |

|

|

|

1.30 |

|

|

|

|

|

|

| |

| Table.6 Mechanical properties for test piece |

No |

Hardness[HRC] |

|

No |

Pure Bendin

Proportional limit[GPa] |

|

No |

Tensile strength[GPa] |

HRC36 |

HRC60 |

|

HRC36 |

HRC60 |

|

HRC36 |

HRC60 |

1 |

32.420 |

58.520 |

|

1 |

0.768 |

2.186 |

|

1 |

1.051 |

1.812 |

2 |

32.660 |

58.980 |

|

2 |

0.776 |

2.216 |

|

2 |

1.072 |

1.857 |

3 |

32.740 |

59.000 |

|

3 |

0.776 |

2.272 |

|

3 |

1.073 |

1.902 |

4 |

34.120 |

59.075 |

|

4 |

0.790 |

2.332 |

|

4 |

1.079 |

1.917 |

5 |

34.260 |

59.080 |

|

5 |

0.826 |

2.344 |

|

5 |

1.088 |

1.985 |

6 |

34.280 |

59.620 |

|

6 |

0.840 |

2.352 |

|

6 |

1.088 |

2.005 |

7 |

34.300 |

59.680 |

|

7 |

0.899 |

2.360 |

|

7 |

1.088 |

2.019 |

8 |

34.740 |

59.720 |

|

8 |

0.921 |

2.369 |

|

8 |

1.089 |

2.023 |

9 |

34.840 |

59.880 |

|

9 |

0.935 |

2.373 |

|

9 |

1.089 |

2.033 |

10 |

35.320 |

59.900 |

|

10 |

0.955 |

2.375 |

|

10 |

1.090 |

2.043 |

11 |

35.400 |

59.940 |

|

11 |

0.975 |

2.379 |

|

11 |

1.092 |

2.054 |

12 |

35.440 |

59.940 |

|

12 |

0.995 |

2.405 |

|

12 |

1.093 |

2.071 |

13 |

35.520 |

59.940 |

|

13 |

0.995 |

2.413 |

|

13 |

1.094 |

2.075 |

14 |

35.600 |

60.000 |

|

14 |

0.995 |

2.427 |

|

14 |

1.095 |

2.080 |

15 |

35.600 |

60.000 |

|

15 |

1.005 |

2.431 |

|

15 |

1.095 |

2.083 |

16 |

35.620 |

60.040 |

|

16 |

1.084 |

2.433 |

|

16 |

1.095 |

2.083 |

17 |

35.800 |

60.220 |

|

17 |

1.114 |

2.439 |

|

17 |

1.095 |

2.097 |

18 |

35.820 |

60.280 |

|

18 |

1.154 |

2.465 |

|

18 |

1.096 |

2.100 |

19 |

35.860 |

60.320 |

|

19 |

1.194 |

2.475 |

|

19 |

1.097 |

2.109 |

20 |

35.880 |

60.340 |

|

|

|

|

|

20 |

1.097 |

2.113 |

21 |

36.460 |

60.340 |

|

|

|

|

|

21 |

1.099 |

2.135 |

22 |

36.480 |

60.360 |

|

|

|

|

|

22 |

1.099 |

2.138 |

23 |

36.520 |

60.420 |

|

|

|

|

|

23 |

1.099 |

2.145 |

24 |

36.700 |

60.440 |

|

|

|

|

|

24 |

1.100 |

2.148 |

25 |

36.800 |

60.620 |

|

|

|

|

|

25 |

1.100 |

2.153 |

26 |

36.820 |

60.640 |

|

|

|

|

|

26 |

1.101 |

2.155 |

27 |

36.820 |

60.700 |

|

|

|

|

|

27 |

1.101 |

2.172 |

28 |

37.180 |

60.720 |

|

|

|

|

|

28 |

1.101 |

2.179 |

29 |

37.220 |

60.800 |

|

|

|

|

|

29 |

1.101 |

2.183 |

30 |

37.780 |

60.900 |

|

|

|

|

|

30 |

1.102 |

2.204 |

|

|

|

|

|

|

|

|

31 |

1.107 |

2.216 |

|

|

|

|

|

|

|

|

32 |

1.112 |

2.262 |

|

|

|

|

|

|

|

|

33 |

1.114 |

2.266 |

|

|

|

|

|

|

|

|

34 |

1.114 |

2.275 |

|

|

|

|

|

|

|

|

35 |

1.120 |

2.318 |

|

|

| |

|

| Fig.1 Distribution of Surface hardness |

| |

|

| Fig.2 Distribution of Proportional limit for pure bending |

| |

|

| Fig.3 Distribution of Tensile strength |

| |

|

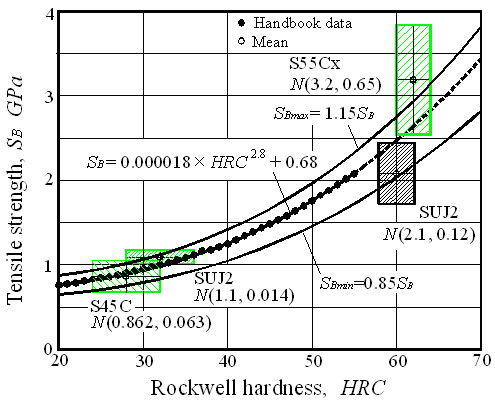

| Fig.4 Correlation between Tensile strength and Rockwell hardness |

|

| |

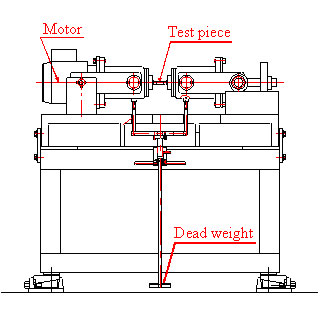

| Table.7 Test machine properties |

Machine type |

4-point rotating bending |

Motor |

φ3-2p-0.75kw |

Frequency |

0~80Hz |

| |

|

|

|

| |

| Table.8 Test piece properties |

| Hardness |

HRC60 |

| Geometry |

|

|

|

| |

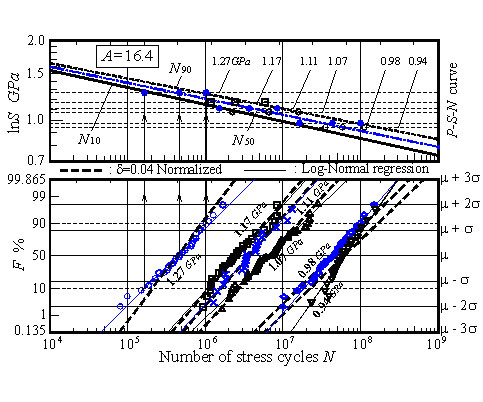

| Table.9 Parameter of Log-normal |

Stress[GPa] |

0.94 |

0.98 |

1.07 |

1.11 |

1.17 |

1.27 |

μ |

17.93 |

17.57 |

15.7 |

15.03 |

14.75 |

12.99 |

σ |

0.53 |

0.64 |

0.77 |

0.63 |

0.68 |

0.76 |

σ/μ |

0.03 |

0.039 |

0.049 |

0.042 |

0.046 |

0.059 |

|

|

| |

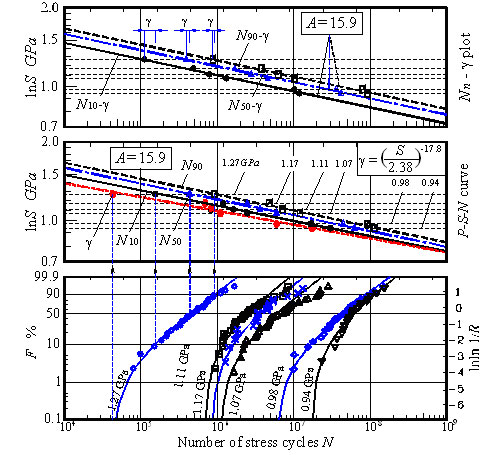

| Table.10 Parameter of 2-parameter Weibull |

Stress[GPa] |

0.94 |

0.98 |

1.07 |

1.11 |

1.17 |

1.27 |

m |

2.17 |

1.84 |

1.75 |

1.95 |

1.89 |

1.71 |

εεφση |

77.80 |

54.90 |

9.40 |

4.45 |

3.30 |

0.63 |

|

|

| |

| Table.11 Parameter of 3-parameter Weibull |

Stress[GPa] |

0.94 |

0.98 |

1.07 |

1.11 |

1.17 |

1.27 |

m |

1.5 |

η |

56.47 |

48.41 |

6.24 |

3.57 |

2.31 |

0.5 |

γ |

17.1800 |

5.9600 |

1.0880 |

0.8390 |

0.6900 |

0.0430 |

|

|

| |

| Table.12 Number of cycle to failures of rotating bending fatigue test for SUJ2 steel (HRC60) |

No |

Stress[GPa] |

1.27 |

1.17 |

1.11 |

1.07 |

0.97 |

0.94 |

1 |

8.00×104 |

8.91×105 |

1.28×106 |

3.32×106 |

1.02×107 |

2.32×107 |

2 |

9.90×104 |

1.05×106 |

1.42×106 |

3.50×106 |

1.53×107 |

3.47×107 |

3 |

1.50×105 |

1.17×106 |

1.70×106 |

|

1.78×107 |

3.67×107 |

4 |

1.87×105 |

1.19×106 |

1.81×106 |

4.28×106 |

2.28×107 |

4.29×107 |

5 |

2.14×105 |

1.21×106 |

1.83×106 |

4.54×106 |

2.50×107 |

4.46×107 |

6 |

2.25×105 |

1.22×106 |

2.96×106 |

4.59×106 |

2.58×107 |

4.53×107 |

7 |

2.53×105 |

1.49×106 |

3.21×106 |

4.73×106 |

2.86×107 |

4.99×107 |

8 |

2.95×105 |

1.65×106 |

3.26×106 |

4.87×106 |

2.98×107 |

5.19×107 |

9 |

3.26×105 |

1.69×106 |

3.34×106 |

4.91×106 |

3.01×107 |

5.37×107 |

10 |

3.31×105 |

1.70×106 |

3.38×106 |

5.12×106 |

3.13×107 |

5.80×107 |

11 |

3.44×105 |

1.76×106 |

3.41×106 |

5.63×106 |

3.43×107 |

5.88×107 |

12 |

3.83×105 |

2.05×106 |

4.46×106 |

6.06×106 |

3.44×107 |

6.00×107 |

13 |

4.04×105 |

2.12×106 |

4.47×106 |

7.24×106 |

3.91×107 |

6.83×107 |

14 |

4.12×105 |

2.24×106 |

4.70×106 |

7.72×106 |

4.18×107 |

7.43×107 |

15 |

4.60×105 |

2.30×106 |

4.78×106 |

7.84×106 |

4.56×107 |

7.48×107 |

16 |

4.71×105 |

2.51×106 |

5.35×106 |

7.98×106 |

4.65×107 |

9.06×107 |

17 |

5.12×105 |

2.57×106 |

5.46×106 |

8.35×106 |

4.91×107 |

9.50×107 |

18 |

5.50×105 |

2.67×106 |

8.26×106 |

8.60×106 |

5.19×107 |

1.01×108 |

19 |

5.57×105 |

3.00×106 |

1.13×107 |

8.89×106 |

5.22×107 |

1.21×108 |

20 |

6.59×105 |

3.05×106 |

1.32×107 |

9.21×106 |

5.58×107 |

1.53×108 |

21 |

6.70×105 |

3.46×106 |

|

9.60×106 |

5.66×107 |

|

22 |

6.96×105 |

3.58×106 |

|

1.15×107 |

6.35×107 |

|

23 |

7.18×105 |

3.73×106 |

|

1.16×107 |

6.47×107 |

|

24 |

7.64×105 |

3.99×106 |

|

1.39×107 |

7.11×107 |

|

25 |

7.67×105 |

4.48×106 |

|

1.53×107 |

7.43×107 |

|

26 |

8.57×105 |

5.71×106 |

|

1.95×107 |

8.65×107 |

|

27 |

8.91×105 |

7.33×106 |

|

2.08×107 |

9.08×107 |

|

28 |

1.11×106 |

7.89×106 |

|

2.18×107 |

1.06×108 |

|

29 |

1.27×106 |

8.28×106 |

|

2.22×107 |

1.11×108 |

|

30 |

1.69×106 |

8.37×106 |

|

2.83×107 |

1.50×108 |

|

|

|

| |

|

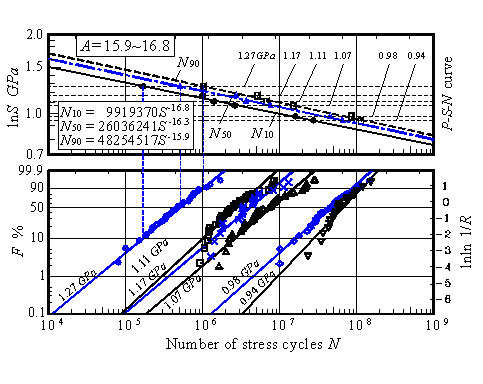

| Fig. 5 Life distribution and Log-normal plot, and Log-normal-based P-S-N curve |

| |

|

| Fig. 6 Life distribution and Weibull plot, and 3-parameter Weibull-based P-S-N curve |

| |

|

| Fig. 7 Life distribution and Weibull plot, and 2-parameter Weibull-based P-S-N curve |

|

| |

| NON-METARIC INCLUSION |

| Table.13 Result of fracture surface[0.98GPa] |

Depth[mm] |

Diameter of inclusion[mm] |

Kind of inclusion |

0.11 |

19.5 |

MgO-CaO-Al2O3 |

0.03 |

6.7 |

TiN |

0.08 |

12.1 |

TiN |

0.47 |

18.4 |

CaO-Al2O3 |

0.03 |

9.7 |

TiN |

0.07 |

8.7 |

TiN |

|

|

| |

| Table.14 Result of fracture surface[1.07GPa] |

Depth[mm] |

Diameter of inclusion[mm] |

Kind of inclusion |

0.02 |

8.1 |

TiN |

0.31 |

14.8 |

TiN |

0.06 |

13.6 |

TiN |

0.01 |

11.2 |

TiN |

0.03

|

9.0 |

TiN |

0.09 |

10.4 |

TiN |

|

|

| |

| Table.15 Result of fracture surface[1.17GPa] |

Depth[mm] |

Diameter of inclusion[mm] |

Kind of inclusion |

0.08 |

15.3 |

TiN |

0.02 |

14.9 |

CaO-Al2O3 |

0.01 |

6.7 |

TiN |

0.36 |

19.5 |

MgO-CaO-Al2O3 |

0.28 |

14.3 |

TiN |

|

|

| |

| Table.16 Result of fracture surface[1.27GPa] |

Depth[mm] |

Diameter of inclusion[mm] |

Kind of inclusion |

0.00 |

9.8 |

TiN |

0.01 |

11.8 |

TiN |

0.24 |

21.5 |

MgO-CaO-Al2O3 |

0.04 |

8.9 |

TiN |

0.04 |

15.0 |

CaO-Al2O3 |

0.05 |

10.2 |

TiN |

|

| |

|

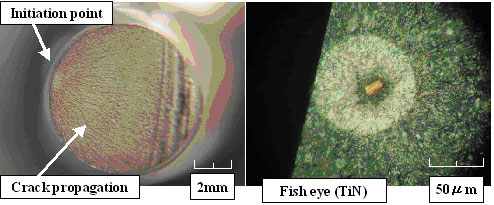

| Fig.8 Fatigue failure of 4-point bending test specimen, SUJ2 HRC58‐62 |

| |

|

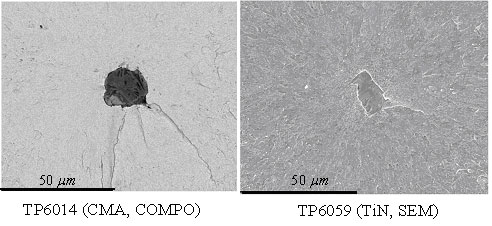

| Fig. 9 TP1014 (CaO-MgO-Al2O3), TP6059 (TiN) inclusions and cracks |

| |

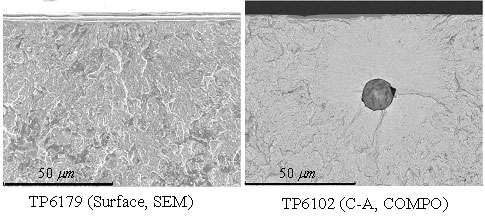

|

| Fig. 10 TP6179 (Surface), TP6102 (CaO-Al2O3) inclusion and its crack |